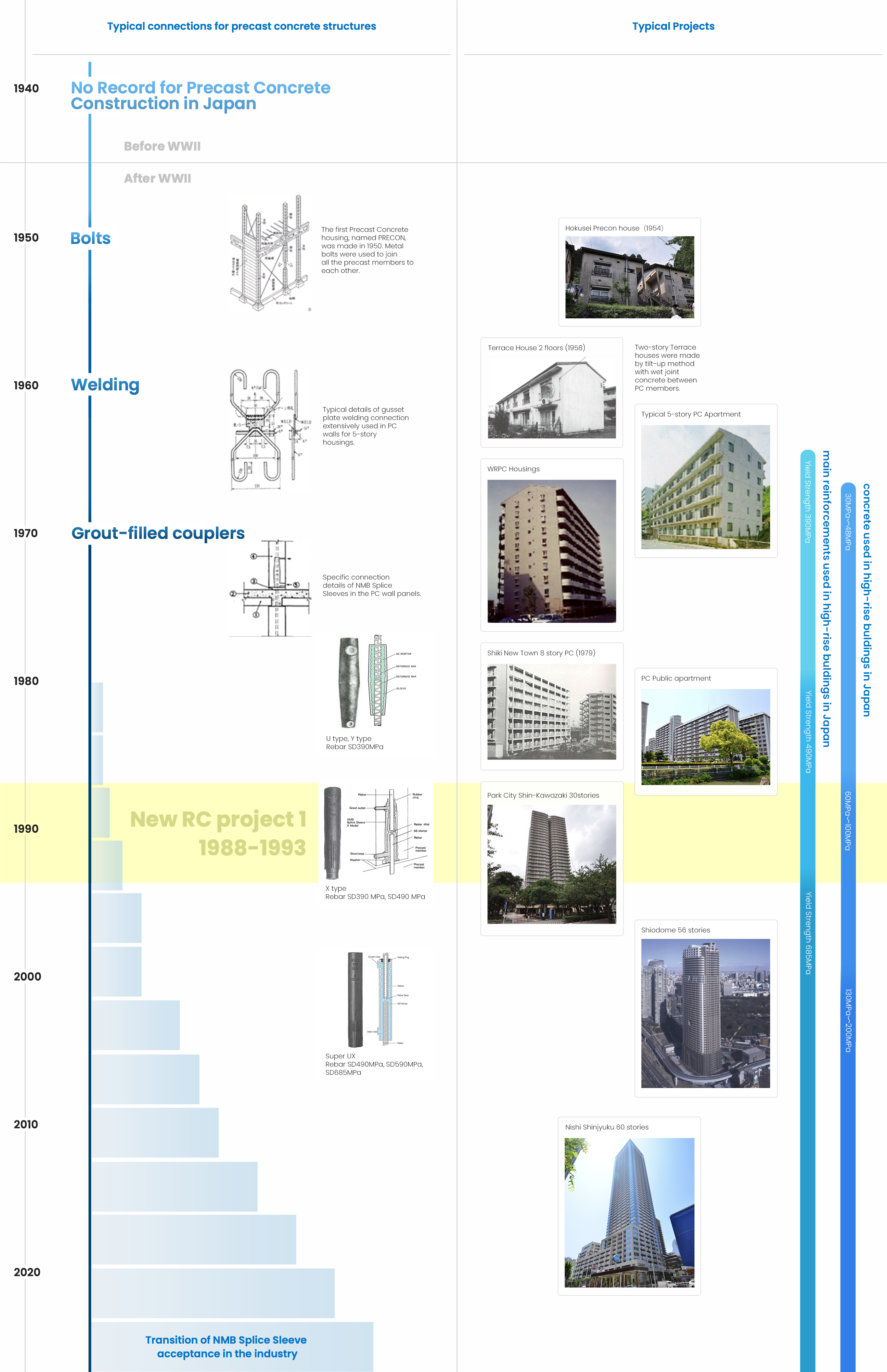

GROUTED COUPLER HISTORY

A History of Precast Concrete

Connections in Japan

Although some ideas and studies have evolved, the history of precast concrete (PC) construction in Japan did not begin before WWII.

The government led the development of the modern PC construction system in Japan due to a severe housing shortage after WWII. Before the birth of NMB Splice Sleeves, the predominant method of connecting precast members was to provide metal parts on the PC members or by welding the protruding main bars. The five (5) story apartments were extensively built by a PC wall system, and the welding bars/gusset plates initially dominated the PC wall connections.

Although these connection methods could effectively connect the PC members, they were susceptible to the weather, the worker's skill easily influenced the quality of the welded portion, and they could not be applied to high-rise structures due to a limited structural capacity.

NMB Splice Sleeves were introduced in Japan in the mid-70s and gradually gained the market. After the successful use of NMB for the eight (8) story PC system in which the welding connection is not applicable due to structural capacity, the NMB was applied for higher buildings such as 15 story WRPC (Wall Rahmen Precast Concrete) system. When the rigid-frame beam-column system has become popular in the precast industry for high-rise to super-high-rise buildings, the NMB has become a standard connection.

More than fifty years have passed since the birth of the grout-filled type coupler. The NMBs are used in skyscrapers with more than 100 floors and other structures, such as bridges, stadiums, airport control towers, etc., outside Japan.

NMB Splice Sleeves have continuously grown along with the precast industry over long years and will continue to support the future of construction technology.